We provide different kind of services related to our specialisation i.e. spare parts delivery, installation, maintenance and other services.

Once the order confirmation, payment confirmation, and drawing approval are received from the customer side, orders are sent to our world-class manufacturing unit for production, quality check, and packaging for dispatch.

We follow instruction manual at all sites for installation of our products so as to bring more efficiency and durability in our installed product.

Our dealers are always equipped with minimum inventory order level of all the major / minor spare parts to reduce the down time.

Knowing the purpose for which the cold room is designed is absolutely necessary. Ultimately that is what helps in achieving perfection in design as well as better output.

A blast freezer is just a freezer which is very cold. Blast Freezers are sometimes referred to as shock freezers. The idea of this type of freezer is to very rapidly bring down the temperature of (usually) foodstuffs or fresh produce, freezing them very quickly.What is blast freezing? The Blast Freeze process requires that food be reduced from a temperature of +70ºC to –18ºC in no more than 240 minutes. Current food legislation requires that all food must be cooled as quickly as possible.

Mortuary cabinets are low temperature refrigerated cabinets that are used to keep dead bodies for short or long time. These dead body refrigerated storage cabinets are widely used at hospitals, railways, airports, disaster & army camps and army hospitals etc.Mortuary freezer box is used to keep dead bodies for a short or long time and is the low-temperature refrigerated cabinets. At hospitals, railways, airports, disaster camps, and the army used such a dead body freezer box.

Blast freezing is a quick freezing technique sometimes used in processing plants to take turkeys quickly to 0 °F (-17.7 °C) or below ensuring optimum safety and quality.Blast chilling is a method of cooling food quickly to a low temperature that is relatively safe from bacterial growth.Simply put, a blast freezer is just a freezer which is very cold. Blast Freezers are sometimes referred to as shock freezers. The idea of this type of freezer is to very rapidly bring down the temperature of (usually) foodstuffs or fresh produce, freezing them very quickly.

Polyurethane Foam (PUF) panel is a layer of material that is sandwiched between GI metal sheets. These panels have many applications and are generally used for making living shelters, especially prefabricated homes, and portable cabins.These panels are primarily used as walling material but can also be used as floor and roof panels. These are non-load bearing panels to be used with structural support frame only.

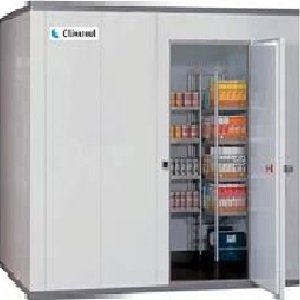

A walk-in cold room is a storage solution for perishable items that need to be frozen or chilled to a specific temperature. Think of a refrigerator, but on a much larger scale. The temperature of a cold room is generated artificially and usually used for commercial refrigeration.A Walk in cold room will operate in temperatures between 0 Deg C to 25 Deg C.

A modular cold room is a type of cold room (or walk-in cold storage) which consist of insulating panels, allowing high-quality insulation to be assembled in any pattern and to any size you need, with quick and easy installation and unique versatility which can be applied to any industry.Modular Cold Rooms are Insulated chambers built at site to desired dimensions and cooling specifications to meet our customer’s requirement.

Walk-in freezer means an enclosed storage space refrigerated to temperatures at or below 32°F that can be walked into and has a total chilled storage area of less than 3,000 square feet.Walk-in refrigerators and freezers are very large, insulated, enclosed spaces used to store and/or display refrigerated or frozen food or other perishable goods. They are used primarily in the food service and food sales industry.

Walk-in refrigerators and freezers are very large, insulated, enclosed spaces used to store and/or display refrigerated or frozen food or other perishable goods. They are used primarily in the food service and food sales industry.Cold rooms, also called walk-ins, are enclosed, refrigerated storage spaces that have footprints generally smaller than 3,000 square feet and can be used for things such as storing perishable food items or packaging food.

Sandwich puf panel means both side metal sheet and insulation in between. They are used alongside traditional building materials such as wood, steel and concrete and have become the first choice material for the realization of various buildings.PUF panels are sandwiched panels made of polyurethane which is usually sandwiched between two metal sheets. Sandwich puf panels are widely used in steel structures in the present day due to their various advantages.To sum up, insulated sandwich panels are the perfect construction materials for modern industrial buildings.

A freezer room is designed to store a range of products and materials at subzero degrees which will prolong the lifespan of food. However, unlike a blast freezer, a freezer room cannot freeze products at a rapid rate.A freezer is an appliance that keeps food frozen at extremely low temperatures. A household freezer is usually built into a refrigerator. It’s where you keep your ice cream and ice cubes.

condensing unit means a component of a ”central air conditioner” which is designed to remove heat absorbed by the refrigerant and to transfer it to the outside environment, and which consists of an outdoor coil, compressor(s), and air moving device. The condensation temperature is that at which a given gas-phase constituent condenses into a liquid. This temperature depends on the physical and chemical state of the system.

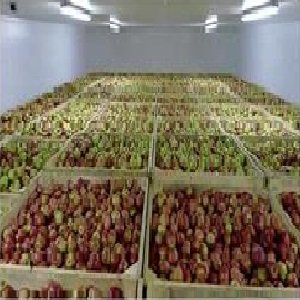

A refrigerating chamber or cold room is a warehouse in which a specific temperature is artificially generated.It is generally designed for storing products in an environment below the outside temperature. Products that need refrigeration include fruits, vegetables, seafood, meat, flowers.The term Cold room, as generic as the name may sound, refers to a specially built room, chamber or an enclosure that is well-insulated or lagged so as to prevent direct thermal flow out of the room.

In an in-rack cooling system, the airflow paths are minimal, requiring a lesser amount of fan energy. Furthermore, the exhaust air is trapped at its hottest point, which maximizes the cooling coil’s delta T. Based on the product, this efficient cooling system utilizes refrigerant or chilled water as the cooling medium.Cooling racks are wire racks that are used on tables and countertops to cool your fresh-from-the-oven baked goods.

A refrigerating chamber or cold room is a warehouse in which a specific temperature is artificially generated.It is generally designed for storing products in an environment below the outside temperature. Products that need refrigeration include fruits, vegetables, seafood, meat, flowers.

Cold storage is a facility that primarily stores food items that are short-lived and highly likely to get spoilt under normal conditions. Cold storage is the primary method for extending the life of fruits. Apples and pears quickly soften and become mealy in texture when kept at ambient temperatures. To maintain the quality longer than one week, fruit must be kept in refrigeration.

We offer the customized Cold Rooms and Refrigeration Cabinets keeping in mind the specific requirements of our clients. We design and engineer these products as per the dimensions and temperature specified by the clients for their specific usage depending upon their particular industry. While designing & Engineering these products we keep in mind the following